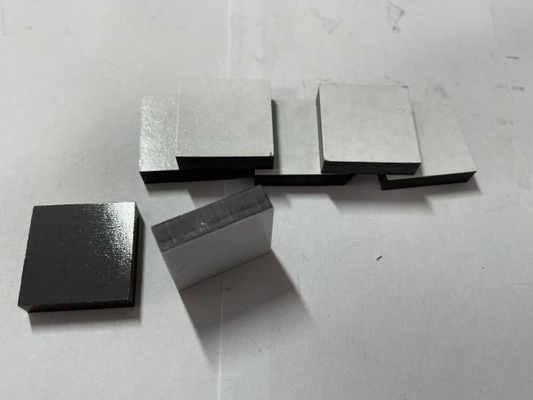

PVC Coating 300GS To1500GS Small Squares Rubber Ferrite Magnets

Rubber Ferrite Magnets For Elevator

Compared with other permanent magnets such as neodymium magnets, samarium cobalt magnets and alnico magnets, ferrite magnets are hard and brittle, with lower magnetic energy. However, they are not easy to demagnetize and corrode, and the production process is simple and inexpensive. Therefore, ferrite magnets have the highest output in the whole magnet industry and are widely used in industrial production.

Introduction of Ferrite Magnets

The raw materials of ferrite magnets are mainly strontium oxide or barium oxide and iron trioxide (in some specific high grades other chemical components such as cobalt (Co) and lanthanum (La) are added to improve their magnetic properties). They are mainly used in speakers, headphones, motors and various instruments.

Product grade list

| Product standards Of Flexible Ferrite Magnet |

|

|

| Version |

2020-02-v03 |

| 页 码 |

1-1 |

| |

|

|

|

|

|

|

|

|

|

|

| Magnetic Properties |

| Material Type |

MGT-RF1 |

MGT-RF1.6 |

MGT-RF2 |

|

|

|

|

|

| Br |

Gs |

1600±200 |

2400±200 |

3000±500 |

|

|

|

|

|

| mT |

160±20 |

240±20 |

300±50 |

|

|

|

|

|

| Hcb |

Oe |

1300±200 |

1750±200 |

2000±500 |

|

|

|

|

|

| kA/m |

100±20 |

150±20 |

159±40 |

|

|

|

|

|

| Hcj |

Oe |

1600±200 |

2600±200 |

3000±1000 |

|

|

|

|

|

| kA/m |

130±20 |

210±30 |

239±80 |

|

|

|

|

|

| (BH)max |

MGOe |

0.7±0.5 |

1.5±0.5 |

2±0.5 |

|

|

|

|

|

| kJ/m3 |

5±1 |

12±1 |

16±4 |

|

|

|

|

|

| Flux Irreversible Loss |

% |

<5 |

<5 |

<5 |

|

|

|

|

|

| (αBr) |

%/℃ |

-0.11 |

-0.11 |

-0.11 |

|

|

|

|

|

| Temperature Coefficient of Br |

| Max Operating Temp |

℃ |

85 |

85 |

85 |

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

| Physical Properties |

| Density |

g/cm3 |

3.6-4.0 |

3.8-4.0 |

3.8-4.2 |

|

|

|

|

|

| Hardess |

Shore D |

30-70 |

| Tensile Strength |

Mpa |

>3.5 |

| Elongation |

% |

20-90 |

| |

|

|

|

|

|

|

|

|

|

|

| Size Range |

| Thickness(mm) |

Range |

0.2-0.3 |

0.4-1.0 |

1.1-2.0 |

2.1-3 |

≥3.1 |

Remark:This data is only applicable to the general situation, and the specific product is determined according to the delivery specifications |

| Tolerance |

±0.03 |

±0.05 |

±0.07 |

±0.1 |

±0.15 |

| Width (mm) |

Range |

1-30 |

31-100 |

101-200 |

201-400 |

401-450 |

| Tolerance |

±0.1 |

±0.15 |

±0.3 |

±0.5 |

±1 |

| Length (mm) |

Range |

1-30 |

31-100 |

101-200 |

201-400 |

≥401 |

| Tolerance |

±0.1 |

±0.15 |

±0.3 |

±0.5 |

1-5 |

| Technical information can be change without furture notice |

Classification of Ferrite Magnets

According to the different production processes, ferrite magnets can be divided into sintered ferrite and bonded ferrite. Among them, sintered ferrites can be divided into dry pressed ferrites and wet pressed ferrites, and bonded ferrites can be divided into extruded ferrite, pressed ferrite and injection molded ferrite.

Ferrite magnets can be divided into isotropic permanent magnets and anisotropic permanent magnets according to whether an external magnetic field is applied during molding. Isotropic sintered ferrite permanent magnets are weakly magnetic, but can be magnetized in different directions of the magnet. Anisotropic ferrite permanent magnets are very magnetic but can only be magnetized in the intended magnetization direction of the magnet.

Soft, flexible, twistable magnets made from bonded ferrite powder and synthetic rubber are also called rubber magnets.

Performance and characteristics of ferrite magnets

1, Ferrite permanent magnets are characterized by high coercivity and low remanence in performance. Ferrite permanent magnets have a high coercivity and strong resistance to demagnetization. They are suitable for working in dynamic magnetic circuit environments with large temperature variations.

2 ,Ferrite permanent magnets are hard and brittle, and can be cut with diamond tools.

3,The main raw material of ferrite permanent magnets is oxide, which is not easy to be corroded and generally does not need electroplating.

4,The working temperature of ferrite permanent magnets is generally in the range of -40℃ to +300℃.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!